Die casting is one of the most widely used manufacturing methods for producing precise, durable, and lightweight metal components. From automotive and aerospace to electronics and industrial equipment, die casting enables mass production of complex parts with excellent surface finishes. By understanding the step-by-step aluminum die casting process, manufacturers and engineers can make informed decisions about material selection, production efficiency, and quality control.

At GRAMOS, we specialize in aluminum die casting services, providing end-to-end support from material selection and high-pressure forming to surface finishing and quality inspection. Our expertise also extends to custom die cast parts manufacturing, enabling us to produce tailored components that meet specific design and industry requirements. In addition, we offer complete automotive die casting solutions for lightweight, high-strength vehicle components that enhance performance, safety, and efficiency. By understanding the step-by-step aluminum die casting process, manufacturers and engineers can see how GRAMOS ensures both efficiency and uncompromising quality.

What Is Die Casting?

Die casting is a metal manufacturing process that involves forcing molten metal into a reusable steel mold, known as a die, under high pressure. This method is widely used for producing parts with precise dimensions, smooth or textured surfaces, and excellent strength.

Unlike traditional casting methods such as sand casting or investment casting, die casting is highly efficient for mass production because each mold can be used thousands of times. This makes it possible to create complex shapes with tight tolerances at a relatively low cost per part.

Raw Materials: Aluminum Ingots as the Foundation

Every successful die casting project begins with the right choice of raw materials. In aluminum die casting, the quality of the ingots directly determines the performance, durability, and consistency of the final product. Aluminum ingots are first melted and refined to remove impurities before entering the casting process. The alloys most commonly used are ADC12 and A380, both known for their excellent combination of strength, durability, and castability. By selecting the appropriate alloy, manufacturers can tailor the properties of the finished components to meet specific industry requirements.

Key benefits:

- Stable chemical composition improves consistency

- Reduces defects such as porosity and shrinkage

- Provides excellent mechanical properties for automotive, aerospace, and industrial applications

Ultimately, investing in high-quality aluminum ingots lays the foundation for a reliable die casting process. It not only improves production efficiency but also enhances the durability and safety of the final product, ensuring components meet both technical standards and customer expectations.

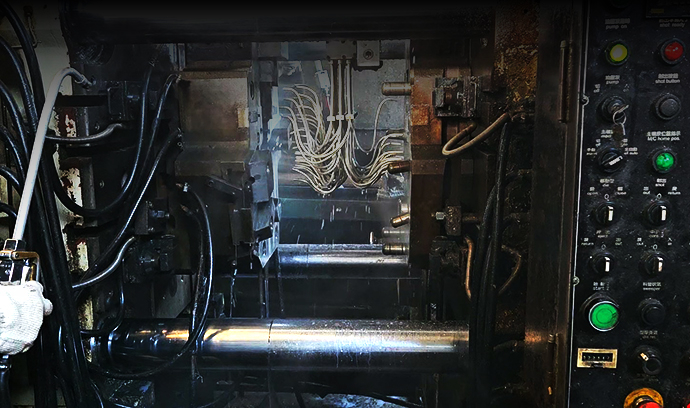

Die Casting: High-Pressure Precision Forming

Once melted and refined, molten aluminum is injected into a hardened steel mold under high pressure, typically ranging from 1,500 to over 30,000 psi. This rapid injection allows the molten metal to fill even the smallest details of the mold cavity, producing components with complex geometries and excellent dimensional accuracy. Because the die can be reused thousands of times, manufacturers achieve high repeatability and consistent quality across large production runs.

High-pressure die casting is particularly suitable for creating thin-walled, lightweight components that still maintain outstanding mechanical strength. The process also minimizes common casting defects such as porosity and shrinkage, while delivering smooth surfaces that often reduce or eliminate the need for secondary machining. Combined, these benefits make high-pressure die casting one of the most cost-effective manufacturing methods for high-volume production.

Advantages of high-pressure die casting:

- Ideal for high-volume production

- Consistent dimensions and smooth surface finish

- Minimizes post-machining requirements

Sandblasting & Surface Treatment

After the die casting process is complete, surface finishing becomes a critical step in ensuring both the functionality and appearance of the final product. Even with high-pressure precision casting, components often have minor imperfections such as burrs, sharp edges, oxidation layers, or residual casting flash. Sandblasting is one of the most effective methods to address these issues and prepare the part for its next stage of production.

Sandblasting involves propelling abrasive media—such as sand, steel shot, or aluminum oxide—at high velocity onto the surface of the cast part. This controlled impact cleans the surface, smooths out rough areas, and creates a uniform texture. The process not only improves the visual appeal of the part but also provides practical advantages for durability and secondary operations.

Why sandblasting matters:

- Enhances surface appearance and texture

- Improves adhesion for secondary processes

- Ensures part-to-part consistency

- Effectively eliminates surface impurities

- Extends component lifespan

Quality Control: Ensuring Excellence in Every Part

In die casting, producing high volumes of components is only valuable if each part meets strict quality standards. That is why quality control is not just a final step but an integral part of the entire manufacturing process. Every die cast component must undergo a comprehensive inspection to ensure that it meets both international standards and the customer’s specific requirements. Every product from Gramos undergoes rigorous inspection before leaving the factory.

- Visual and dimensional inspection

- 3D scanning or coordinate measuring (CMM)

- Pressure testing or X-ray inspection for hidden defects

Quality control ensures every die cast component meets international standards and customer requirements.

Get Started with GRAMOS Die Casting Services Today

GRAMOS provides professional custom aluminum die casting services tailored to your specific project requirements. From precise material selection and high-pressure forming to advanced surface finishing and rigorous quality control, our team ensures every component meets the highest standards of performance and reliability. Whether you need parts for automotive, aerospace, electronics, or industrial applications, GRAMOS, a leading aluminum die casting supplier in Taiwan, has the expertise and equipment to deliver consistent, high-quality results. Contact GRAMOS for Your Die Casting Project!