- Home

- Knowledge

- Case Studies

- Industry Application

Industry Application

Precision in Aerospace Aluminum Components

Key Standards and Practices for Processing and Inspection of Aerospace Aluminum Parts

From material selection to quality verification, we build the first line of defense for flight safety

The aerospace industry has extremely high requirements for the reliability and precision of materials and parts. Aluminum alloys are widely used in aircraft structures, internal mechanisms and other high-performance components due to their light weight, high strength and good corrosion resistance. To ensure flight safety and structural integrity, the processing and inspection procedures of aluminum parts must strictly follow international standards and customer specifications.

Whether you need design input or supplier support, GRAMOS delivers trusted aerospace component consultation and seamless access to Taiwan’s top-tier production partners.

The Role of Aluminum in Aerospace Manufacturing

Aluminum is one of the most widely used materials in the aerospace industry due to its:

• Light weight — critical for fuel efficiency

• High strength-to-weight ratio — ensuring structural integrity

• Excellent corrosion resistance — for long service life

• Machinability — enabling tight tolerances and complex geometries

Common aluminum alloys used in aerospace:

• 7075-T6: High strength, used in structural parts

• 6061-T6: Versatile and weldable

• 2024-T4: Excellent fatigue resistance

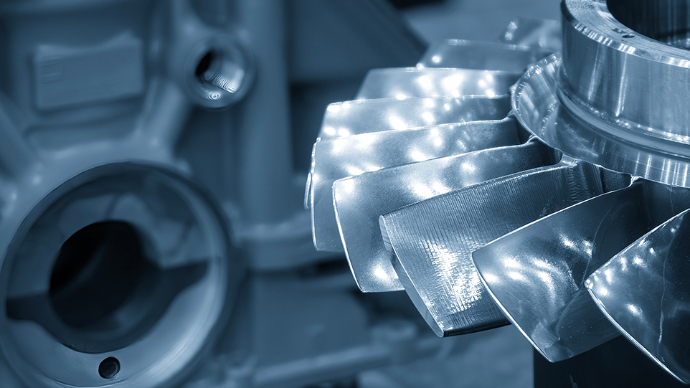

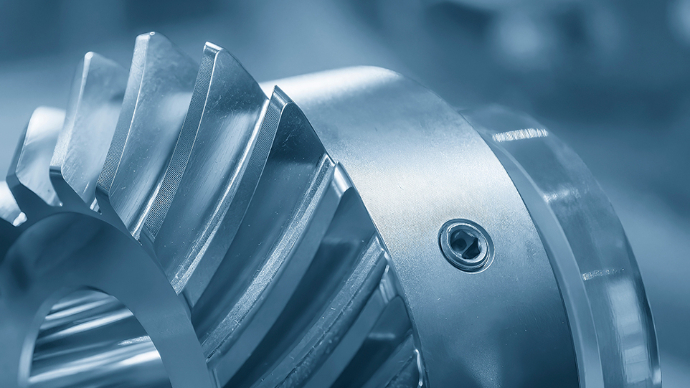

Aerospace Machining Standards

To meet strict aviation safety requirements, aerospace aluminum parts are manufactured under stringent conditions:

• Tight Tolerances: Typically within ±0.01 mm

• 5-axis CNC Machining: Ensures multi-angle precision

• Special Fixtures: Minimize vibration and deformation during milling

• Traceability: Every part must be fully documented and traceable

Inspection Protocols & Quality Assurance

No aerospace component leaves the factory without passing multiple layers of inspection:

• Dimensional Checks: Using CMMs and laser scanners

• Non-Destructive Testing (NDT): Including X-ray, ultrasonic, and dye penetrant testing

• Material Certification: Compliant with ASTM and NADCAP standards

• Documentation & Reports: Full inspection reports, PPAP, and FAI records provided