- Home

- Knowledge

- Case Studies

- Thermal Technology Spotlight

Thermal Technology Spotlight

Understanding Heat Sink Performance

Heat Sink Fundamentals:

Natural vs. Forced Convection

Heat sinks work by transferring heat away from components, helping them maintain safe operating temperatures. The performance of a heat sink largely depends on convection, which can be either:

Natural Convection

- Relies on air movement caused by temperature differences

- No fans or blowers required

- Quieter, energy-efficient, and ideal for low-power systems

Forced Convection

- Uses fans or other active airflow devices

- Dramatically increases heat dissipation efficiency

- Ideal for high-power or enclosed environments

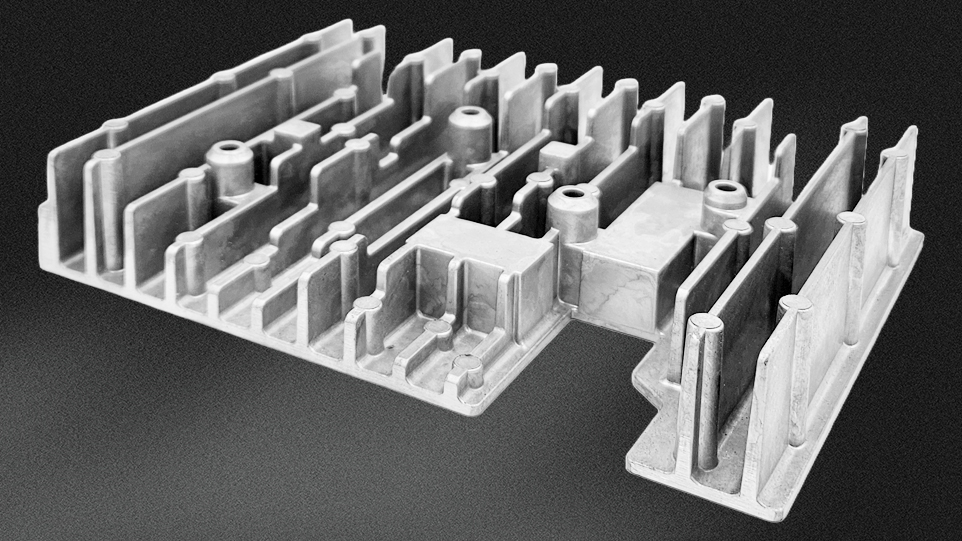

Aluminum Extrusion vs. Die-Cast Heat Sinks

Both manufacturing methods have their strengths, depending on design complexity, performance, and production volume.

Recommendation:

- Use extruded heat sinks for high thermal performance and simple shapes

- Use die-cast heat sinks for compact, intricate designs where space-saving is critical

| Feature |

Extruded Aluminum |

Die-Cast Aluminum |

| Structure |

Linear fin profiles |

Complex, 3D geometries |

| Surface Finish |

Smooth, uniform |

Can require post-treatment |

| Thermal Conductivity |

Higher (due to material purity) |

Slightly lower |

| Design Flexibility |

Limited to straight profiles |

Highly customizable shapes |

| Cost Efficiency |

Ideal for medium/large runs |

Cost-effective for high volumes |

How to Choose the Right Heat Sink Based on Power

Proper thermal management starts with power output. Here's a basic guide:

Don't forget:

- Selection also depends on ambient temperature, material, surface area, and airflow conditions.

| Power Dissipation |

Suggested Type |

Cooling Method |

| 0–10W |

Small extruded heat sink |

Natural convection |

| 10–50W |

Medium extruded or die-cast |

Natural or assisted |

| 50W+ |

Die-cast with fins + fan |

Forced convection or heat pipe |